Box Cutter Vs Utility Knife: Key Differences Explained

When you’re tackling a project, the right tool can make all the difference. Imagine reaching for a trusty blade, but you’re faced with a choice: box cutter or utility knife?

Which one truly suits your needs? This decision might seem trivial, but choosing wisely could save you time, effort, and maybe even a few fingers. You want efficiency and safety, but you also want to ensure you’re not wasting money on the wrong tool.

Dive into this article to uncover the hidden strengths and weaknesses of each option. Discover which tool is the perfect match for your tasks, and ensure your projects are completed with ease and precision. Your next cut could be your best one yet!

Box Cutter Basics

In the world of cutting tools, the box cutter and utility knife are essential for everyday tasks. These tools, while similar in purpose, have unique features. Understanding their differences can help you choose the right tool for your needs. Let’s delve into the basics of the box cutter, a staple in many toolkits.

Design And Structure

The box cutter is known for its simple design. It typically features a handle and a retractable blade. This design makes it easy to use and safe to carry. Most box cutters have a lightweight plastic or metal body. This ensures durability without adding extra weight. A quick slide mechanism allows the blade to retract, preventing accidents.

Blade Material

Box cutters usually have blades made from stainless steel or carbon steel. These materials provide strength and sharpness. Carbon steel blades are known for their edge retention. Stainless steel blades resist rust and corrosion. Both options ensure efficient cutting and long-term use.

Safety is a key aspect of box cutter design. Many models include a locking mechanism. This keeps the blade in place during use. Retractable blades add an extra layer of safety. Some box cutters come with a blade guard. This protects the user and extends the blade’s life.

- Opening cardboard boxes

- Trimming materials like wallpaper and carpet

- Cutting through packing tape

Box cutters are versatile. Their compact design makes them ideal for quick tasks. Whether at home or work, they efficiently handle various materials. Their reliability makes them a go-to tool for many users.

Utility Knife Essentials

Choosing between a box cutter and a utility knife can be tricky. Both tools are essential in various tasks. Understanding the basics of a utility knife is crucial before making a decision. These knives are versatile, offering precision and safety features. They are used in tasks ranging from crafting to cutting through tough materials. Knowing what makes utility knives special can help you choose the right tool for your needs.

What Is A Utility Knife?

A utility knife is a tool designed for general-purpose cutting. It features a sharp, replaceable blade. You can use it for tasks like opening packages or cutting cardboard. These knives are popular among DIY enthusiasts and professionals.

Features Of Utility Knives

- Retractable Blade: This feature ensures safety. You can retract the blade when not in use.

- Replaceable Blades: Utility knives allow easy blade replacement. This ensures sharpness and efficiency.

- Ergonomic Handle: A comfortable grip reduces hand fatigue.

- Durable Construction: Made from sturdy materials for long-lasting use.

Types Of Utility Knives

| Type | Description |

|---|---|

| Folding Utility Knife | Compact and portable. Easy to store and carry. |

| Fixed Blade Utility Knife | Offers stability. Ideal for heavy-duty tasks. |

| Retractable Blade Utility Knife | Safety-focused design. Blade retracts into the handle. |

Benefits Of Using A Utility Knife

- Versatility: Suitable for various tasks.

- Precision Cutting: Ideal for detailed work.

- Safety Features: Retractable blades reduce injury risk.

- Ease of Use: Simple design ensures user-friendly operation.

Common Uses Of Utility Knives

Utility knives are used in many settings. You can use them for cutting ropes, trimming edges, and crafting. They are handy in workshops, homes, and offices. Their ability to slice through different materials makes them invaluable. Always ensure the blade is sharp for the best results.

Design Differences

Box cutters and utility knives are essential tools for many tasks. Though they may seem similar, they have distinct design differences. These differences cater to various needs and preferences. Understanding these differences can help you choose the right tool for your projects. In this section, we will explore the design differences between box cutters and utility knives, focusing on blade types and handle structure.

Blade Types

Box cutters and utility knives feature different blade types that suit specific tasks. Box cutters typically have a thinner, more compact blade. This design is perfect for cutting through cardboard and similar materials. Their blades are usually retractable, enhancing safety when not in use.

- Box Cutter Blades:

- Thin and sharp

- Retractable for safety

- Ideal for cardboard and light-duty tasks

Utility knives, on the other hand, offer a variety of blade options. These blades are often sturdier and thicker. They are designed to handle heavier materials such as carpet, rope, and plastic.

- Utility Knife Blades:

- Thicker and more durable

- Various shapes available

- Suitable for heavy-duty cutting

The table below summarizes the key differences:

| Feature | Box Cutter | Utility Knife |

|---|---|---|

| Blade Thickness | Thin | Thick |

| Safety | Retractable | Non-retractable or fixed |

| Use | Light-duty | Heavy-duty |

Handle Structure

The handle structure of box cutters and utility knives also shows key differences. Box cutters have a simple, often plastic handle. This design prioritizes lightweight and ease of use. The handle usually includes a slider to control the blade’s position.

- Box Cutter Handles:

- Lightweight plastic

- Simple design

- Slider for blade control

Utility knives, in contrast, have a more robust and ergonomic handle. Made from metal or durable plastic, these handles provide a firm grip. This is important for precision in heavy-duty tasks. The design might include features like a rubber grip or finger grooves.

- Utility Knife Handles:

- Sturdy metal or plastic

- Ergonomic design

- Enhancements for grip and comfort

A comparison of handle features:

| Feature | Box Cutter | Utility Knife |

|---|---|---|

| Material | Plastic | Metal or durable plastic |

| Design | Simple | Ergonomic |

| Grip | Basic | Enhanced for comfort |

Credit: riteknife.com

Common Uses

Box cutters and utility knives are essential tools for various tasks. Each has unique features that make them suitable for different jobs. Understanding their common uses can help you decide which tool is best for your needs. Let’s explore how these handy tools are used in different scenarios.

Packaging

Box cutters and utility knives are often used in packaging due to their ability to slice through materials with ease. They are especially useful in environments where quick and clean cuts are necessary. Here’s how they are commonly used:

- Opening Boxes: Both tools efficiently cut through packing tape and cardboard.

- Cutting Straps: Utility knives can handle thicker plastic straps with ease.

- Trimming Materials: Box cutters offer precision for trimming excess materials around packages.

Both tools are indispensable in warehouse and retail settings. Their sharp blades make them perfect for breaking down boxes for recycling. A simple table below highlights their strengths:

| Task | Box Cutter | Utility Knife |

|---|---|---|

| Opening Boxes | Excellent | Good |

| Cutting Straps | Good | Excellent |

| Trimming | Excellent | Good |

Crafting

Crafting projects often require precision and versatility. Box cutters and utility knives are perfect for various crafting tasks. Here are some common uses in crafting:

- Cutting Paper: Box cutters make precise cuts in paper and thin cardboard.

- Shaping Foam: Utility knives work well for shaping craft foam and styrofoam.

- Trimming Fabric: Both tools can trim fabric for sewing and other craft projects.

Craft enthusiasts appreciate the control these tools offer. The sharp blades allow for intricate designs and clean edges. Whether working with paper or fabric, these tools are invaluable in a crafter’s toolkit.

Diy Projects

For DIY enthusiasts, box cutters and utility knives are must-have tools. They handle a variety of tasks around the home. Here are some common DIY uses:

- Cutting Carpets: Utility knives are ideal for cutting carpets to size.

- Installing Wallpaper: Box cutters offer the precision needed for clean wallpaper edges.

- General Repairs: Both tools can be used for trimming and cutting materials for repairs.

These tools are perfect for those who enjoy home improvement projects. Their versatility makes them suitable for cutting through various materials. With a box cutter or utility knife, DIY projects become easier and more efficient.

Safety Features

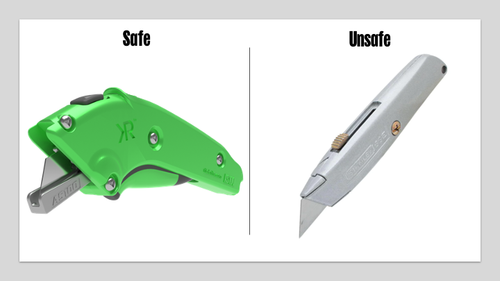

Box cutters and utility knives are indispensable tools in various industries and households. Each serves similar purposes but differs in design and functionality. One critical aspect where they differ is in their safety features. Ensuring safety while using sharp tools is paramount, and understanding the unique safety features of each can help users make informed choices. Let’s delve into the specifics of blade retraction and locking mechanisms.

Blade Retraction

Blade retraction is a vital safety feature in both box cutters and utility knives. This feature allows users to retract the blade into the handle, minimizing the risk of accidental cuts.

Box cutters typically use a spring-loaded mechanism for blade retraction. This design automatically pulls the blade back when pressure is released. It’s particularly useful for quick tasks where speed and safety are essential.

- Automatic retraction ensures the blade is not exposed longer than necessary.

- Reduces the risk of cuts when the tool is not in use.

Utility knives, on the other hand, often feature a manual retraction system. Users control the blade position by sliding it into the handle. This design provides flexibility for tasks requiring extended blade exposure.

- Allows for better control over blade length.

- Useful for cutting through thicker materials.

Understanding these retraction mechanisms can significantly impact user safety and efficiency.

Locking Mechanisms

Locking mechanisms are integral to preventing unintended blade movement. They ensure the blade remains in place during use, enhancing safety and precision.

Box cutters often feature a simple lock mechanism. This mechanism holds the blade in a fixed position until manually adjusted. It’s effective for straightforward tasks and offers ease of use.

- Reduces risk of blade slipping during a cut.

- Ideal for repetitive tasks requiring consistent blade position.

Utility knives, meanwhile, may incorporate a more advanced locking system. This includes multi-position locks, allowing users to adjust the blade to various lengths securely.

- Offers greater versatility for diverse cutting needs.

- Ensures blade stability for precision work.

Choosing the right locking mechanism depends on the tasks at hand and individual safety preferences.

Credit: www.sinotools.com

Maintenance Tips

Box cutters and utility knives are essential tools for many tasks. Their sharp blades make cutting easy, but they need care to work well. Regular maintenance ensures they remain efficient and safe. Below, you’ll find useful maintenance tips for keeping your box cutters and utility knives in top shape. Learn how to sharpen blades and clean tools effectively.

Sharpening Blades

Keeping the blades sharp is crucial for smooth cutting. Dull blades can lead to accidents and inefficient work. Follow these tips to sharpen your blades:

- Use a Sharpening Stone: A sharpening stone or whetstone is ideal for this task. Hold the blade at a 20-degree angle and move it across the stone.

- Consider a Blade Sharpener: If using a stone seems challenging, a blade sharpener is a good alternative. It’s user-friendly and provides consistent results.

- Check the Blade Angle: Ensure the blade is consistently angled. This prevents uneven sharpening, which can reduce blade effectiveness.

Table comparing sharpening tools:

| Tool | Ease of Use | Effectiveness |

|---|---|---|

| Sharpening Stone | Moderate | High |

| Blade Sharpener | Easy | Moderate |

Cleaning Tools

Cleaning your tools is as important as sharpening them. Dirt and debris can dull blades and affect performance. Here are steps to clean your tools:

- Disassemble the Tool: If possible, take apart the tool. This helps in cleaning hard-to-reach areas.

- Use a Soft Brush: Use a soft brush to remove dust and debris. It’s gentle yet effective.

- Wipe with a Damp Cloth: A damp cloth can remove any stuck-on grime. Ensure the cloth is not too wet to avoid rust.

- Dry Thoroughly: Always dry the tool completely after cleaning. Moisture can lead to rust and corrosion.

Regular cleaning extends the life of your tools. It ensures they function safely and efficiently. Remember, a clean tool is a happy tool!

Cost Comparison

Choosing between a box cutter and a utility knife often boils down to several factors. Among these, cost is a critical consideration. Understanding the cost difference helps in making an informed decision. Both tools serve similar functions, but their costs can vary significantly. Let’s explore the cost aspects of box cutters and utility knives.

Cost Of Box Cutters

Box cutters are generally more affordable. They are designed for simple tasks. These tools often come with basic features. This keeps the price low. You can find basic box cutters for as little as $2 to $5. Premium models, with added safety features, may cost more. Yet, they rarely exceed $15.

Cost Of Utility Knives

Utility knives tend to be pricier. They offer versatility and durability. Basic utility knives usually start around $5 to $10. For heavy-duty or retractable models, prices can range from $15 to $30. Some high-end brands may charge even more. The added cost often reflects improved materials and design.

Cost-benefit Analysis

Making a choice involves evaluating what you need. Box cutters are ideal for light, everyday tasks. They cost less and are easy to replace. Utility knives offer more features. They can handle tougher jobs. Although they cost more upfront, they offer durability.

Comparison Table

| Feature | Box Cutter | Utility Knife |

|---|---|---|

| Price Range | $2 – $15 | $5 – $30 |

| Durability | Moderate | High |

| Features | Basic | Advanced |

Both tools have their merits. Consider your needs and budget. Choose the tool that best fits your tasks. Balance cost with functionality for the best value.

Credit: www.youtube.com

Choosing The Right Tool

Deciding between a box cutter and a utility knife can be challenging. Both tools offer unique advantages, but choosing the right one depends on your specific needs. Consider factors like the tasks at hand and your personal preferences. This decision impacts efficiency and safety. Explore these aspects to make an informed choice.

Task-specific Choices

Different tasks require different tools. A box cutter excels in slicing through cardboard and tape. It’s ideal for opening packages quickly. The small blade makes precise cuts. A utility knife, on the other hand, is versatile. It handles tougher materials like carpet or linoleum. It’s suitable for heavy-duty tasks.

- Box Cutter Uses:

- Opening boxes

- Cutting tape

- Light materials

- Utility Knife Uses:

- Cutting carpet

- Trimming wood

- Heavy materials

Consider the project requirements. A box cutter offers precision for delicate cuts. A utility knife provides strength for tougher tasks. Understand the material you’ll be cutting. This aids in choosing the right tool.

User Preferences

Personal preferences play a crucial role. Some users prefer the compact design of box cutters. They’re lightweight and easy to handle. Others opt for utility knives due to their sturdiness. Evaluate the comfort and grip.

Many find box cutters easier to use for quick tasks. Utility knives offer more control for detailed work. Consider safety features. Box cutters often have retractable blades. Utility knives might have blade locks.

| Tool | Pros | Cons |

|---|---|---|

| Box Cutter | Lightweight, precise cuts | Limited to light materials |

| Utility Knife | Versatile, strong | Heavier, bulkier |

Think about ease of use. Grip comfort is important during long tasks. Choose a tool that fits well in your hand. This reduces strain and enhances accuracy. Prioritize safety and efficiency in your selection.

Frequently Asked Questions

A box cutter is lighter and simpler. A utility knife is sturdier with replaceable blades.

No, a box cutter is best for light tasks like opening packages. Not heavy-duty work.

Both are safe with proper use. Utility knives often have safety locks for extra protection.

Yes, utility knife blades are replaceable. This makes them versatile and cost-effective over time.

Consider your task. Box cutters for light tasks; utility knives for tougher materials. Choose based on need.

Conclusion

Choosing between a box cutter and utility knife depends on your needs. Box cutters are great for slicing boxes and light materials. Utility knives offer more versatility and can handle tougher tasks. Consider safety features and comfort when picking one.

Both tools have their strengths. Your decision might hinge on specific tasks or preferences. Think about how often you use the tool. Also, consider the materials you work with most. Both tools can be valuable additions to your toolbox. Make a choice that fits your lifestyle and work demands.

Related Post: Leatherman vs Swiss Army Knife: Which Multi-Tool Wins in 2025?